Part 1 The chips problems in the process of machining Alumium alloy

Chips always is a difficult problem in the high speed cutting, boring process. It has small allowance, high linear speed, the cutting heat will increase intensely with the time increasing, if the chips are not removed in time, it will product the following problems:

(1) Chips Winding the cutters, which will lead to scrap the workpiece surface, and lower the surface quality and dimension tolerance.

(2) Chips will harm the insert, which will reduce the tool life

(3) Chips will harm the workers and affect the efficiency, because the workers need use hand to remove the chips.

Part 2 PCD Chipbreaker Inserts for Chips Breaking

In order to solve above chips problems, most cutting tools manufacturers try to design the chipbreakers to help the manufacturers. Halnn design special PCD Chipbraker Insert through changing the design dimension, choosing suitable cutting parameters, and finally help the customers improve their problems on the chips.

Halnn offered the following solutions:

(1) Choose the PCD Insert with good chips breaking performance, Halnn can help design the chipbreakers as the customers’ requirements.

(2) Change the insert tip angle, because the angle can control the chips flow direction, if increase the Rear corner and front angle, which will make the insert tips more sharp, and machining faster.

(3) Choosing the suitable cutting parameters depending on the cutting requirements

|

Component Materials |

Recommend Halnn PCD Grade |

Vc(m/min) |

Fr(mm/r) |

Ap(mm) |

|

Aluminum Alloy |

4~8% Si |

CDW010 |

CDW302 |

CDW005 |

CDW850 |

100~5000 |

0.03~0.5 |

0.1~3.0 |

|

9~13% Si |

CDW010 |

CDW302 |

|

CDW850 |

100~3000 |

0.03~0.5 |

0.1~3.0 |

|

>13% Si |

CDW010 |

CDW302 |

CDW005 |

CDW850 |

100~2500 |

0.03~0.4 |

0.1~2.5 |

Part 3 The application of Halnn PCD Chipbreaker Insert in aluminum alloy machining

(1) When machining the inner bore with high hardness aluminum alloy A6061 materials, if with common pcd insert without chipbreakers, the chips will be long and can’t be interrupted easily, and will affect the surface quality; if with Halnn PCD chipbreaker Insert, the chips can be interrupted into small pieces, and can be removed easily, which will help obtain good surface quality.

(2) When machining Die casting aluminum alloy ADC12 materials, if machining with pcd insert without chipbreakers, the chips will be curly, and can’t be removed, if machining with Halnn pcd chipbreaker Insert, the chips can be cutting into small pieces, and be removed in time.

Part4 Advantages of Halnn PCD Chipbreaker Insert

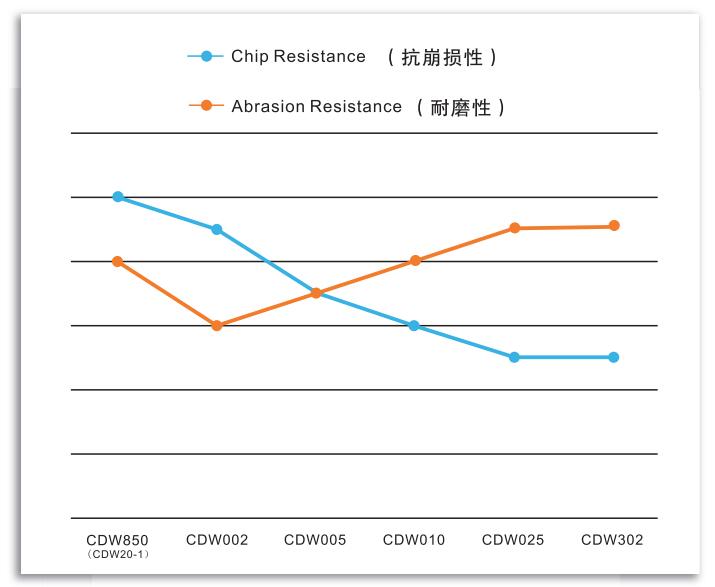

Halnn can offer PCD Chipbreaker Insert with the following PCD Grade: CDW010,CDW005,CDW025, CDW302 and CDW850, it will have good abrasive resistance, Resistance to chipping, is very suitable for machining Aluminum alloy and other non-ferrous metal, both roughing and finishing process.

If you would like to know more details or have any needs on PCD Chipbreaker Insert, please feel free to contact with us info@halnntools.com.