The application Industry of PCD End Mills

Category:News

PublishedDate:2018-05-15

PCD Tools are made of supehrad materials polycrystalline and the tool base through special process. PCD EndMills are mainly used for high speed milling.

Applicatio Industry: 3C, Automotive Aerospace,ect.

Machining Materials: Aluminum alloy and other non-ferrous metal, carbon fiber and other composite,ect.

PCD Materials Characteristics

1.The hardness of PCD can reach 8000 HV, is about 8~12 times of tungsten carbide.

2.The thermal conductivity of PCD is 700W/mK, which is 1.5 to 9 times that of tungsten carbide, and even higher than that of PCBN and copper, so the heat transfer of PCD tool is rapid.

3.The friction co-efficient of PCD is generally only 0.1 to 0.3 (the friction coefficient of tungsten carbide is 0.4 to 1), so the PCD tool can significantly reduce the cutting force;

4.The coefficient of thermal expansion of PCD is only 0.9 × 10 ^ -6 ~ 1.18 × 10 ^ -6, which is equivalent to only 1/5 of tungsten carbide, so the thermal deformation of PCD tool is small, and the machining accuracy is high.

5.The affinity between PCD cutting tools and non-ferrous metals and non-metallic materials is very small. Chips do not easily adhere to the tool tip to form built-up edge during processing.

Halnn PCD Grade and Characterisitcs

http://www.halnncbn.com/CBN_PCD/PCD_Materials/

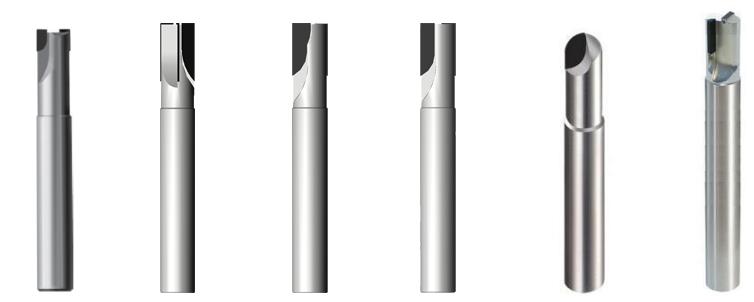

PCD End Mills models

http://www.halnncbn.com/CBN_PCD/PCD_Materials/

Other Special PCD End Mills

Application Industry with PCD End Mills

If you would like to know something about PCD End Mills, please feel free to contact with us info@halnntools.com