Characteristics and Application of PCD Insert

Category:News

PublishedDate:2018-05-03

Part 1 PCD Insert Materials Properities

1. Low thermal expansion coefficient

2. Low friction coefficient

3. Thermal conducdicity

4. Radioactive inertia

5. High hardness

6. High refractive index

Part 2 Halnn PCD Materials Grade

|

Grade |

Granularity(μm) |

Characteristics |

Application |

|

CDW850 |

Submicron |

Ultra-fine grain structure, strong edge sharpness and edge durability |

High precision machining, mirror surface machining, suite for aluminum alloy that required high on the chipping performance, mainly used for machining Ti alloy and other composites |

|

CDW002 |

2μm |

High cobalt content, Good electrical machine performance, excellent toughness, Good roughness machining, more convinent for complec tool processing |

Mainly used for engrave milling cutter and thread cutting tool, and also cutting tools for wear-resistant parts, used in woodworking saws, particleboard and the tools for machining silicon aluminum alloy |

|

CDW005 |

5μm |

Excellent electric spark and machinability, good toughness, wear resistance and edge quality |

It suits for good surface quality processing, mainly used for machining PMMA, Silicion alloy and metal cell phone shell outlin and used in the wood cutting tools, saws industry |

|

CDW010 |

10μm |

Universal PCD Grade, good toughness and high abrasive resisitance |

Suit for single tool for rough machining, especially for wood molding, medium and low silicon aluminum alloy parts (such as piston). |

|

CDW025 |

25μm |

High wear resistance and edge quality |

Suit for high Silicion Aluminum alloy, MMC, Tungsten carbide and ceramic, graphite,wear resistant parts, mainly used in wood Wood finishing insert and saws |

|

CDW302 |

2~30μm |

Mixed 2μm and 25μm,good wear resistance and edge quality and edges strength |

It mainly used for machining MMC, high Silicion Aluminum calloy, high strength cast iron and other application. |

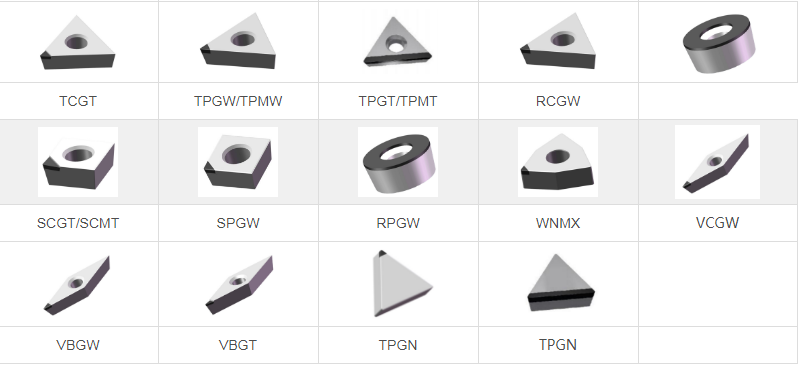

Part 3 ISO PCD Insert Image

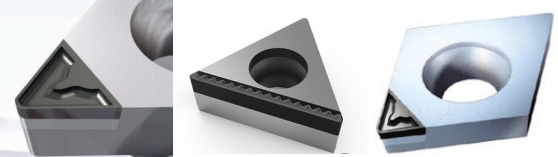

Part 4 New PCD Chipbreaker Insert

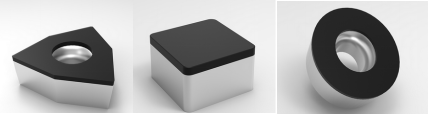

Part 5 PCD Insert with full face

Part 6 Application of PCD Insert