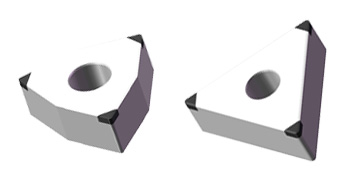

Hard Turning Inserts from Halnn Superhard

Category:News

PublishedDate:2018-01-09

Part 1 Halnn CBN Inserts for hard turning hardened steel

Gear Steel, Bearing Steel, Die Steel, tool steel all belong to hardened steel, the hardness after heat treatment will be above HRC50. Specific for these typical materials, Halnn has corresponding cbn grade and cutting parameters, the following is the cutting condition of some typical component.

|

Hardened Steel component |

Halnn CBN Grade(Finishing) |

Cutting Condition |

|

Gears |

BN-H10 |

ap= 0.2 |

Fr=0.1 |

Vc=180 |

|

Metallurgical Bearings |

BN-H11 |

ap= 2.5 |

Fr=0.12 |

Vc=140 |

|

Ball Screw |

BN-S20 |

ap= 4.5 |

Fr=0.10 |

Vc=90 |

|

Synchronizer |

BN-H20 |

ap= 0.15 |

Fr=0.1 |

Vc=170 |

|

Mold |

BN-S200 |

ap= 0.5 |

Fr=0.12 |

Vc=130 |

Above tablet, BN-H10,BN-H11 and BN-H20 belong to brazing pcbn insert, only can be used for finishing process. BN-S200 belong to solid cbn inserts, and can be used for semi-finishing and finishing process.BN-S20 also belong to solid cbn inserts, not only have high hardness, but also have good abrasive resistance and impact toughness, which make it possible that interrupt turning hardened steel with cbn inserts.

Part 2 Halnn CBN Inserts for hard turning high hardness cast iron or cast steel

High Chromium Cast Iron, White cast iron, ni-hard cast iron, abrasive resistant and heat resistant steel, high speed steel all belong to high hardness castings. Specific for above high hardness materials, Halnn also researched some cbn grades, please kindly check the following tablet:

|

High hardness castings |

Halnn CBN Grade |

Cutting Condition |

|

Industry Pump |

BN-K1 |

ap=3.5 |

Fr=0.5 |

Vc=75 |

|

Engine Block |

BN-S300 |

ap=0.5 |

Fr=0.25 |

Vc=850 |

|

High Speed Steel Rolls |

BN-S20 |

ap=0.5~1 |

Fr=0.2 |

Vc=50 |

|

Crushing Cone(High Manganese steel) |

BN-S20 |

ap=7.5 |

Fr=0.3 |

Vc=180 |

|

High Chromium Alloy Cast Iron Rolls |

BN-K1 |

ap=4 |

Fr=4 |

Vc=55 |

All above cbn grade belong to non-metal adhesive solid cbn inserts, BN-S300 is for finishing process, and other 2 grades BN-K1 and BN-S20 can be used for both roughing and finishing process.

Part 3 Halnn CBN Inserts for high speed machining cast iron

Gray cast iron mainly is Pearlite gray cast iron, such as FC200, FC250,FC300, ect, and Ductile Cast Iron include QT500,QT600 and QT700,ect. Common typical gray cast iron component include brake disc,brake drum. Both of them are the main component in automotive industry. It required high precision. Halnn BN-S30 is the special grade for high speed machining brake disc. The cutting condition of brake disc for semi-finishing brake disc:ap=2.5mm, Fr=0.45mm/r,Vc=350m/min. If finish turning brake disc, we will recommend BN-S300 solid cbn insert and BN-K20 brazing pcbn insert, The cutting condition is ap=0.25mm,Fr=0.2mm/r,Vc=800m/min. And it can obtain high precision.

Part 4 Halnn cbn insert for machining other materials (superalloy, Powder metallurgy)

Powder Metallurgy is porous structure, which make it difficult to machine. Specific for this problem, Halnn researched corresponding cbn grade and suitable cutting condition as follows:

|

Materials that difficult to machine |

Halnn CBN Grade |

Cutting Condition |

|

Powder Metalurgy parts |

BN-K50 |

ap≤0.5 |

Fr= 0.1-0.25 |

Vc=150-230 |

|

Ni-based superalloy |

BN-S200 |

ap≤0.5 |

Fr= 0.15 |

Vc=350 |

Part5 Summary

With the development of the machine tools industry, more and more materials appear, which is difficult to machine. And Halnn will continue to research new cbn grade to help meet the customers’ requirements.

If you have any problems on hard turning inserts,please feel free to contact with us info@halnntools.com