Ni-based alloy and Halnn CBN Inserts

Category:News

PublishedDate:2017-12-29

As we all know that Ni-based alloy is one type excellent material used in aerospace and Military industry.TheYield Strength is 192MPa, the cutting force is 50% higher than 45 steel, the Thermal Conductivity is about 20% of 45 steel, and it is easily produce BUE. So Ni-based alloy is a kind typical materials that difficult to machine. In current times, there are 3 type cutting tools can be used for machining ni-based alloy: carbide insert, ceramic cutters, cbn inserts, and cbn inserts will be the most suitable one.

Insert Materials:

BN-S200 and BDN80 Solid CBN Insert

Suit Machining Condition

Cutting Data:

|

Machining Materials |

Vc(m/min) |

Fr(mm/r) |

ap |

CBN Grade |

|

Ni-based alloy(≥HRC35) |

100~200(Roughing) |

0.1~0.25 |

1~10 |

BN-S200/BDN80 |

|

180~450(Finishing) |

0.1~0.3 |

0.5~2.0 |

|

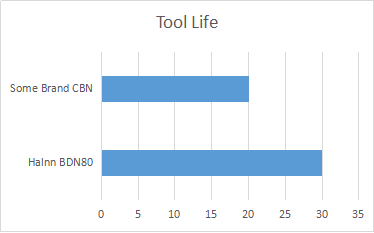

Application Case 1

|

BDN80 Solid CBN Insert machining Inconel 718(HRC45~47) |

|

Insert Grade:BDN80,Vc=350m/min,Fr=0.15mm/r,ap=0.5mm |

Compared

with

other CBN |

|

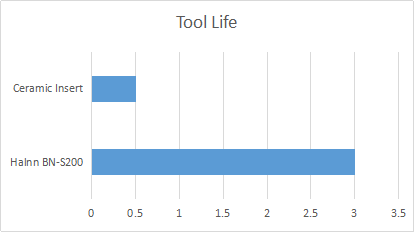

Application Case 2

|

BN-S200 Solid CBN Insert machining Spraying rolls(HRC50) |

|

Insert Grade:BN-S200,Vc=180m/min,Fr=0.1mm/r,ap=2mm |

Compared

with

other CBN |

|