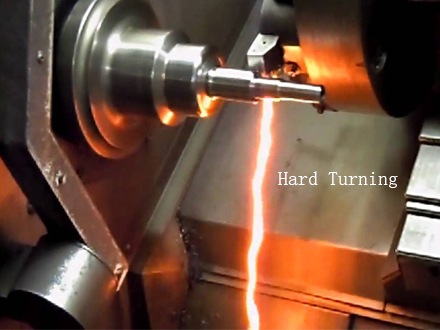

Hard Turning supported by machine tools and Cutting tools

Category:News

PublishedDate:2017-12-27

In hard turning process, the component has high hardness, high cutting temperature, which required the cutting tools have excellent abrasive resistance and heat resistance, and the machine tools need be rigid enough.

1.The choice of the cutting tools for hard turning

(1) Coating Carbide Insert: Coating a thin layer of refractory metal or non-metallic refractory with good abrasive resistance with vapor deposition method on the cemented carbide substrate surface, in order to improve the tool life. Normally the thickness of the coating layer is 2~18μm, if the component hardness is too high, the process is long, once the surface wear layer worn out, the inserts also will wear seriously, so coating carbide insert are more suitable for hard turning the materials which hardness is below HRC45.

(2) Ceramic Insert: It has high hardness, wear resistance, and the cutting speed will be 3 times higher than carbide insert. However ceramic insert is brittle, only suit for finishing process with small allowance, and can’t meet interrupt turning condition. Normally ceramic cutters only suit for continuous turning the component hardness between HRC45~55.

(3) CBN Inserts: CBN Insert is consisted by cubic boron nitride powder and little binder in high temperature and high pressure. The hardness is only second to diamond tools, so cbn inserts and pcd inserts are both called superhard cutting tools.

CBN Insert is researched specific for high hardness non-ferrous metal, has high hardness and strong impact toughness, and is widely used for high chromium cast iron, chilled cast iron, hardened steel, gray cast iron, ect. The cutting speed can be 2 times higher than ceramic inserts.

CBN Insert have 2 types: solid cbn insert and brazing pcbn insert. Solid CBN Inserts can be used for roughing and semi-finishing process, however pcbn inserts perform better for finishing process.

2. The cutting parameters requirements of hard turning

The cutting parameters affect seriously on hard turning. Higher the component hardness, Smaller the cutting speed. If it required high on the component precision, we need to choose small cutting depth. And the cutting details can be determined by the surface roughness and the efficiency.

Cbn inserts have good heat resistance and abrasive resistance, and can be used for high speed machining,large cutting depth and small feed rate. Ceramic insert is only second to cbn inserts, mainly used for finishing process. Carbide Insert wear quickly, not suit for high speed machining and large cutting depth.

3. Machine Tools for hard turning

Comparing with hard turning hardened steel and other materials, the cutting force increase more than 50%, and the power need increase about 2 times, so the machine tools for hard turning need have good rigidity. If thus, it can express the advantages of hard turning, and can make sure the requirements of high precision and high requirements.

If you would like to know more details on hard turning, please feel free to contact with us info@halnntools.com