High Speed turning hardened steel with CBN Inserts instead o

Category:News

PublishedDate:2017-12-26

Because of the high hardness of the hardened steel, the manufacturers usually use grinding process as the final process to realize finishing processing. The appearance of cbn inserts make it possible that turning instead of grinding, which also improve the process efficiency.

CBN Inserts can be used for “turning instead of grinding” hardened steel, gray cast iron, powder metallurgical materials. And it adopts dry cutting process, avoid the pollutions that grinding process brought in and also protect the environment.

Halnn Superhard, as the predecessor of China superhard cutting tools, already made cbn inserts and high grade diamond tools for machining brittle hard materials as research direction, and already enjoyed high reputation in superhard cutting tools field.

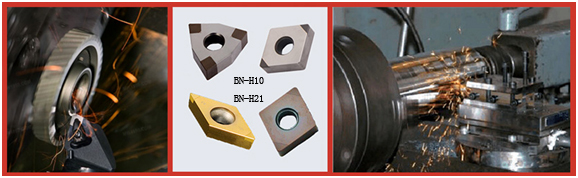

Halnn CBN Inserts can perform stable in strict environment, especially for hard turning hardened steel, can ensure the size and roughness requirements. For interrupt turning condition process, Halnn CBN Inserts perform excellent, Halnn have researched BN-H10 and BN-H21 PCBN Inserts specific for continuous and interrupt turning process, also can offer coating inserts and wiper inserts.

The advantages of Halnn PCBN Inserts:

(1) Lower the invest costs with turning lathe instead of grinding machine tools

(2) Turning process can be finished with one cycle, which can save the cycle time.

(3) It has high efficiency than grinding process

(4) Lower the costs on per component.

(5) Dry cutting process protect the environment

One of the application case as follows:

|

BN-H21 PCBN Insert hard turning Hardened Steel |

|

Workpiece materials |

20CrMnTi |

|

|

Hardness |

HRC58~62 |

|

Machining Condition |

Interrupt Cutting |

|

Insert Model |

BN-H21 WNGA080408,Fr=0.1mm/r,ap=0.2mm |

|

Cutting Data |

Vc=127m/min |