Finish Turning Gears with Halnn CBN Inserts Grade

Category:News

PublishedDate:2017-12-22

Gears, as the most important part in machines, are widely use CNC Lathe, automotive industry. With the increasing competition of gears industry, how to improve the efficiency and reduce the costs at the same time is a key point. Hard turning will be the best methods to solve all the problems.

Hard turning is a process that making turning gears as the final process, and the process quality can replace grinding process, also called as “Turning instead of Grinding”.

The advantages of hard turning gears comparing with grinding process:

(1) Invest costs: Turning lathe only need about 10%~30%, not only reduce invests of the lathe tool, but also improve the efficiency.

(2) Product quality: In the turning process, the chips can take away 80% heat, which avoid the crack in the grinding process.

(3) Machining Efficiency: The efficiency of turning process is 4~6 times of grinding process.

(4) Working condition: Turning Gears usually use dry cutting process, which can realize pure production, and can make sure good working environment, and the chips can be reclyed.

The choice of the cutting tools materials for hard turning gears

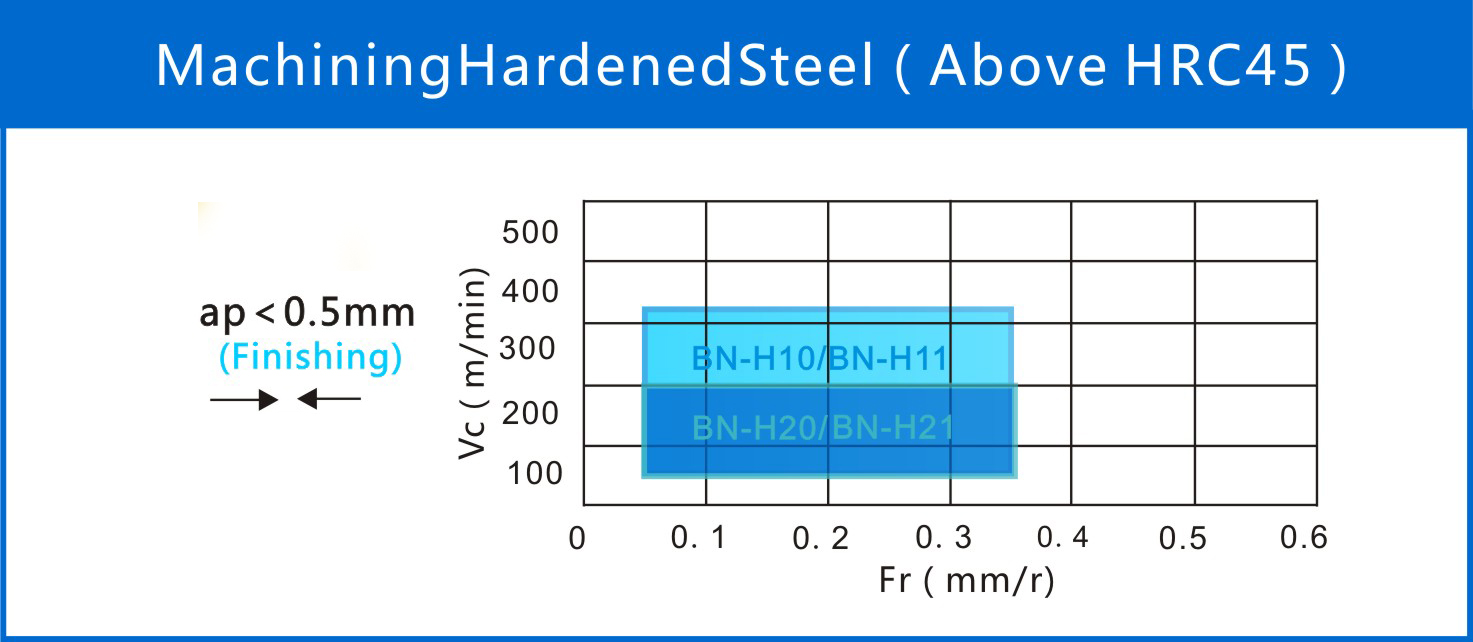

It required high on the cutting tools for hard turning gears, especially required strictly on the gears size and surface roughness, even interrupt turning condition. In current times, the manufacturers usually use imported pcbn insert for hard turning gears. Specific for hard turning gears, Halnn researched BN-H10 and BN-H21 PCBN Insert for continuous and interrupt turning condition, both of them have excellent cutting performance, also have reasonable price.

The advantages of BN-H10 and BN-H21 PCBN Insert finish turning gears: