Hard Turning Bearings instead of Grinding Speeds and Feeds A

Category:News

PublishedDate:2017-11-01

With the development of the global economy, wind power have developed as one type clean energy. And wind power bearings, as one of the main component in wind power machine tools, usually have bad working condition, so it require high on the temperature,Humidity and load range. In order to extend the working time, the manufacturers usually use heat treatment to improve the characteristics of the wind power bearings. The hardness of the bearings which get through heat treatment will be high, the manufacturers usually use grinding as the final process in the past.

With the increasing competition of the bearings market, hard turning instead of grinding already become widely used in wind power bearing industry. It has high efficiency, low costs, grinding process can’t meet these requirements. However it propose big challenge for the impact resistance and wear resistance of the cutting tools.

Specific for high hardness wind power bearings after heat treatment, the turning tools need have the following performance:

(1)The tool need high hardness, wear resistance, High temperature resistance

(2)It has enough bending strength and impact toughness.

(3)It has excellent machining stability and Antioxidant performance.

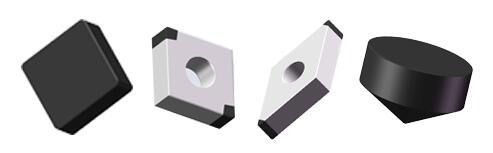

For above requirements on the cutting tools, Halnn researched 3 type cbn grades: BN-H11, BN-S200 and BN-S20.

BN-H11 belong to brazing pcbn insert, which can be used for continuous turning condition, and have good wear resistance and anti-collapse, suit for high speed machining hardened steel. The tool life will be about 5~6 times of ceramic insert with high cutting speed.

BN-S200 belong to solid cbn insert, have excellent wear resistance, and are mainly used for semi-finishing and finishing process of the bearings, and can ensure high surface roughness.

BN-S20 also belong to solid cbn insert, not only can remove large working allowance, but also can obey heavy interrupt turning condition. It has high hardness, excellent thermal shock resistance and wear resistance, the tool life will be several times of ceramic cutters.

The cutting data as follows:

|

Machining Materials |

Cutting Speed Vc (m/min) |

Cutting Depth ap (mm) |

Feed Rate Fr (mm/r) |

Halnn CBN Grade |

|

Bearings (>HRC45) |

50~150 (Roughing) |

1~10 |

0.15~0.7 |

BN-S20 |

|

60~250 (Finishing) |

<1 |

0.05~0.35 |

BN-S20,BN-S200, BN-H11 |

The following will share two application cases of PCBN Insert hard turning bearings with hard turning speeds and feeds

(1)Finish turning the Bearing Roller, and End Surface, hardness is HRC47~55, the allowance is less than 2mm, we recommend BN-S200 solid cbn insert, the speeds and feeds as follows: ap<1, Fr=0.05~0.35mm/r, Vc=60~250m/min.

The machining effect: the tools life is 7 times of ceramic cutters, and the surface roughness can be controlled with Ra0.6~1.0.

(2) Finish turning Cylindrical and Surface, the hardness is HRC47~55, the channel hardness is HRC55~62, the working allowance is above 2mm, we recommend Halnn BN-S20 solid cbn insert, the cutting speeds and feeds as follows: ap=1mm, Vc=140~180m/min

The machining Effect: Long tool life, can replace grinding process, the surface roughness can arrive Ra0.4

When turning bearings instead of grinding, we need to choose suitable cutting tools materials and insert models depending on the bearing hardness, working allowance, working condition and machining site, so before you buy any cutting tools, you’d better contact with us, we can help you choose the suitable one depending all the technological information you offered.

Our contact way as follows: info@halnntools.com, skype:info@halnntools.com, Whatsapp:+8615617635382, Wechat: Halnntools.