The problems on machining bearings and the solutions with cb

Category:News

PublishedDate:2017-10-30

The difficult problems of hard turning bearings:

(1)High hardness after heat treatment, above HRC55,

(2)Large deformation for large scale bearing,

(3)Short tool life with common cutting tools,

(4)Low process efficiency with grinding process.

Because of bad working environment for the bearings, it required high on the bearing performance and the precision, Halnn recommend to use cbn insert, and the manufacturers can choose different cbn grade specific for different working allowance.

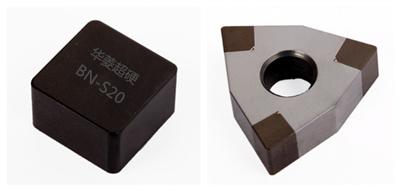

For metallurgical bearings, the margin usually is within 0.5mm, and we can choose brazing pcbn insert, and this type cbn insert are mainly researched for finishing process. Halnn recommend BN-H11 CBN Insert, and the precision can reach Ra0.8.

For wind power bearings, the size is usually large, and the precision require high, and the allowance usually is with 2~6 mm, the deformation will be large; for this condition, we can choose solid cbn insert, which can reduce the steps, improve the efficiency. The working allowance of Halnn BN-S20 solid cbn insert can reach 4mm.

Halnn Superhard, the previous institute of Henan Superhard Materials, one of the most biggest manufacturer of superhard cutting tools in China, first proposed ‘Solid CBN Insert’ for roughing process. With more than 10 years experience on hard materials, Halnn already become one of the most famous cbn tools companies in China.