The problems and solutions on hard turning bearings

Category:News

PublishedDate:2017-10-25

1. The hardness of the bearings after heat treatment will be above HRC50, traditional cutting tools will be not wearable, low efficiency, what can we do?

A:In order to obtain excellent performance and usage life, the manufacturers usually use heat treatment to improve the hardness, wear resistance and impact resistance. So the bearing is difficult to machine. Traditional cutting tools hardness is not enough, and will be easily chipping,which will affect the efficiency seriously.

In current times, cbn insert is the right choice for hard turning bearings. Specific for finishing process, Halnn research non-metal adhesive solid cbn insert BN-S200, pcbn insert BN-H11 and BN-H20. And BN-H20 belong to brazing pcbn insert, suit for small allowance, and the cutting depth need to be control within 0.5mm.

For example, Halnn Bn-H11 pcbn insert hard turning HRC62 metallurgical bearings, compared with other pcbn insert, the inner bore and Cylindrical roughness can reach Ra0.8 with same cutting speed Vc=140m/min. And the tool life will be longer than other pcbn insert.

2. In order to not affect the size precision of the large scale bearings, it often has large working allowance, but brazing pcbn inserts also need several steps to finish the whole process, and the efficiency is still slow, how can we solve these problem?

A:For large scale, it has large allowance, both traditional cutting tools and brazing pcbn insert can’t satisfy the requirements. In this condition, Halnn research BN-S20 solid cbn insert which can be used for large allowance and interrupt cut bearings.

If the bearing diameter is large, it will easily deform after heat treatment, and it needs finishing process to ensure the size and precision requirements. Grinding efficiency is low, only using turning process. The allowance with BN-S20 usually is above 2mm, and the cutting depth can reach 0.8mm. If the allowance of the bearing is 3mm, it only need one step, and the efficiency will improve several times.

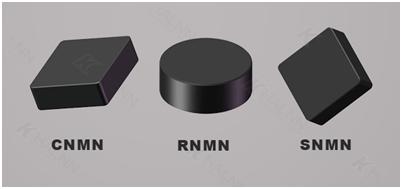

And specific for different parts of the bearings, Halnn has special cutting tools and tool holders. The details of hard turning bearings are as follows for reference:

|

Machining part |

Tool Holder |

Halnn Grade |

Insert Model |

|

Surface |

CGDNN |

BN-S20 |

SNMN150716,SNGN120712 |

|

Surface shoulder |

CCLNR/L |

BN-S20 |

CNGN120412,CNGN120408 |

|

Channel |

CRDNN |

BN-S20 |

RNGN120400,RNGN090300 |

|

CRDCN |

BN-S20 |

RCGX120700,RCGX090700 |

If you have any problems, please feel free to contact with us info@halnntools.com, skype:info@halnntools.com, Wechat:Halnntools, Whatsapp:+8615617635382