Cutting tools for finish machining 52100 (GCr15) Bearings

Category:News

PublishedDate:2017-10-18

52100(GCr15) bearings, as the main hardened steel part, is difficult to machine, when you meet some problems, please contact with Halnn, we can help you solve these problems.

Common problems that appears in the process of finish turning 52100(GCr15) bearings

(1) The harndess is not high, the tool don't have good wear resistance

(2) In order to satisfy the precision, it needs change the insert frequently, the efficiency is low, and the tool cost is high.

The hardness of 52100 bearings usually are above HRC50, and some metallurgical bearings will reach HRC62. For this type high hardness workpiece, cbn insert is the right choice for machining 52100 bearings. In early times, the manufacturers use carbide insert, however the carbide insert itself hardness is not high, and it is not wear resistant, so need change the insert frequently.

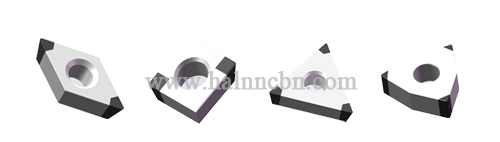

The hardness of CBN insert is about HRC98.5, and can be used in high temperature condition, is the best cutting tools materials for machining ferrous metals. Specific for 52100 bearings, cbn insert is the right choice. Especially BN-S20 solid cbn inserts and BN-H11 PCBN inserts, both of them perform well.

One application case of finish turning 52100 (GCr15) bearings:

|

Insert Description |

Workpiece Details |

|

Insert Model |

DNGA150408 |

Component |

Metallurgical bearings |

|

Previous Cutting Tools |

Other PCBN insert |

Mateirals |

GCr15 |

|

Cutting Data |

Component shape |

|

Vc(m/min) |

60-250 |

|

|

Fr(mm/r) |

0.05-0.35 |

|

ap(mm) |

≤1 |

|

Machining Effect: With same cutting data, the tool life with BN-H11 is higher than other brand PCBNm and each tool cost reduce, the roughness can be ensure with Ra0.8. |

Any more information, please feel free to contact with us info@halnntools.com, Whatsapp:+8615617635382, wechat: Halnntools