The cutting tools materials for machining pump parts

Category:News

PublishedDate:2017-09-29

With the development of the economy, pump products have been widely used all over the world, and this industry has been developed. And most pump products belong to castings. As the development of the technology, it required higher than before on the pump quality, they need to meet the requirements that improve efficiency, lower the noisy and extand its life. Most of manufacturers make Hi-Cr cast iron as the main materials of the pump products, because of its excellent wear resistance.

However, when using High chromium cast iron as the pump parts materials, especially for large pumps, it will have sand, stomach problems, the products will not only have high hardness, but also have unaverage allowance, which make it difficult to machine.

Specific for High Chromium Cast Iron parts, manufacturers choose carbide insert first, however it has low efficiency, which also will affect the product quality. And In the process, the cutting speed of carbide insert is low, together with the sand, stomach defects, the efficiency is low and the cost is high.

For high chromium cast iron, cbn insert will be the right choice, because CBN is the best material for machining ferrous metal in current times. The hardness of carbide insert will be HRC71~76. However the hardness of cbn will be about HRC98. And cbn insert can realize high speed machining, which will improve the efficiency.

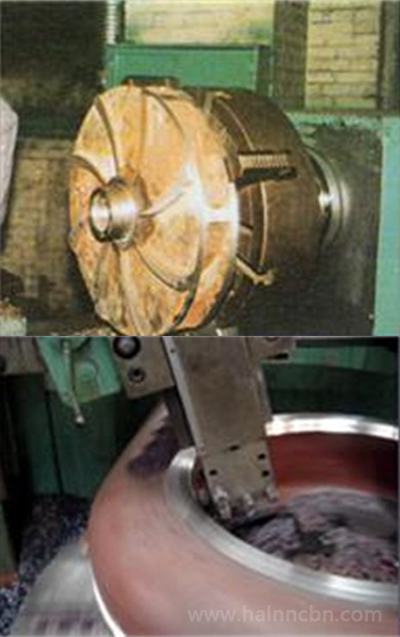

Traditional cbn insert is brazing pcbn insert, which is mainly for finishing process. When meet large working allowance and interrupt turning condition, it is not suitable. BN-K1 Solid CBN Insert researched by Halnn can be the right tool, because BN-K1 use ceramic as the binder, which improve the impact resistance. BN-K1 can be used for interrupt turning and large allowance machining. So BN-K1 has been widely used all over the world.

|

BN-K1 solid cbn insert machining pump |

|

Materials

|

High Chromium Cast Iron Cr26

|

|

|

Hardness

|

HRC58~60

|

|

Workpiece

|

Impeller, Pump Body

|

|

Insert

|

BN-K1 SNMN120712,CNMN120712

|

|

Machining Type

|

Interrupt turning, Dry Cutting

|

|

Cutting Data

|

Ap=3.5mm, Fr=0.1mm/r,Vc=75m/min

|

|

Machining Effect |

|

Insert Materials |

Cutting Speed (m/min) |

Feed Rate Fr (mm/r) |

Tool Life/blade |

|

Halnn BN-K1 |

75 |

0.1 |

85 |

|

Ceramic Insert |

35 |

0.07 |

10 |

More information on machining pump parts with BN-K1, please click http://www.halnncbn.com/Cases/Mining_Machine_Industry/ , Or feel free to contact with us info@halnntools.com, skype:info@halnntools.com