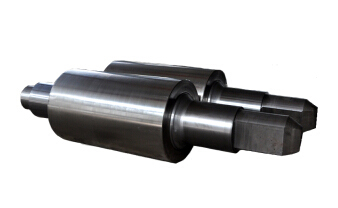

Machining HSS Rolls with Halnn BN-S10 Solid CBN Inserts

Category:News

PublishedDate:2017-09-26

In Current times, Most of HSS Rolls are Hi-Carbon High Speed Steel Rolls, with the development of the technology, more and more manufacturers use this type HSS Rolls, and the hardness will be above HRC63, so it will required higher on the efficiency of the cutting tools.

The advantages of HSS Rolls

1. High-speed steel roll has high content carbon, and contains high content chromium, molybdenum, niobium and other alloying elements, carbide has high hardness and good wear resistance;

2. High-speed steel roll has good thermal stability;

3. High-speed steel roll has a good harden ability, to ensure that the roll from outside to inside with the same good wear resistance. ;

4. High-speed steel material expansion coefficient, good thermal conductivity

Cutting Tools Choice of machining HSS Rolls

High-speed steel roll has high hardness, it required high on the cutting tools materials, especially for the cutting tools on heavy turning condition, the cutting tools will need better wear resistance and impact resistance.

In early times, the manufacturer use carbide insert, and it will wear rapidly, and need to change the insert frequently. Especially when meet HSS Rolls which hardness is above HRC63, it can’t machine.

Then ceramic insert appears, but it is brittle, and only can be used for small allowance finishing process. It can't be used for roughing process.

Nowadays the appearance of cbn inserts make it easily for machining HSS Rolls, Normally it adopt solid cbn inserts, it not only can achieve large working allowance machining, but also has excellent wear resistance, and the tools life will be several times than traditional cutting tools.

And the tools that be widely used in current times are solid CBN Insert BN-S10, which is researched by Halnn Superhard specific for HSS Rolls. And it is the most ideal cutting tools for heavy turning in nowadays. And already used by the customers from all over the world.

The application case of BN-S10 solid cbn inserts machining HSS Rolls

When BN-S10 solid cbn insert machining HSS Rolls, it has excellent wear resistance and heat resistance, and it can stand high temperature which will above 1000℃, and realize heavy turning, and reduce the cutting times, improve the efficiency. BN-S10 solid cbn insert use dry cutting type, which can reduce the environment pollution and lower the costs.

It will have different cutting parameters for different process and working allowance, for example:

Roughing Process: Vc=35~120m/min,Feed Rate: Fr=0.15~0.7mm, Cutting Depth ap=1~10mm

Finishing Process: Vc=60~180m/min, Feed Rate: Fr=0.05~0.35mm, Cutting Depth ap≤1mm

Halnn Superhard, as the pioneer of cbn inserts in China, is one of the most famous brand in China. And we already have mature solutions and cutting tools in cast iron and hardened steel industry. Halnn always insist “Tailored” Service for customers, and help them solve their problems on high speed cutting.

Any problems on high speed cutting or high hardness materials, please feel free to contact with us info@halnntools.com, skype:cbn_inserts_angles, Whatsapp:+8615617635382