Machining Wearable sets with Solid CBN Inserts BN-K1

Category:News

PublishedDate:2017-09-18

Wear-resistant sets is one of main parts in mining machinery industry, we all know about mining machinery industry, most of the parts belong to wear resistant parts, and they help the machinery improve their performance and improve the efficiency.

In order to obtain a good service life, it adds nickel alloy elements which hardness will be above HRC60, traditional cutting tools can’t be used.

In current times, only cbn inserts can machine wear resistant sets, and cbn insert is the best cutting tools materials of machining high hardness casting parts. Especially solid cbn insert, it can rough machining high hardness casting parts, and the tolerance can arrive 7.5mm, but the insert model need to be decided by the machining condition.

For example, Halnn superhard, the biggest manufacturer of cbn insert, since established, already researched cbn insert. With more than 10 years experience on superhard cutting tools, Halnn already researched more than 20 kinds of cbn inserts grade, and they have been already widely used in mining industry, heavy machinery, automotive parts and lathe industry.

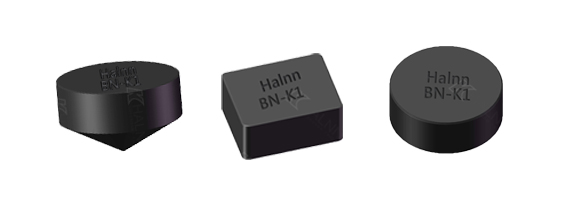

BN-K1 Solid CBN Inserts, which is Halnn researched specific for wear resistant parts, not only can machine the wearable sets with large margine, and has long tool life.

The following is one application case on machining wearable sets with BN-K1 solid cbn inserts

Workpiece Diameters: 960mm

Machining Site: Cylinder

Machining allowance:3mm

Hardness: HRC60

Lathe: Vertical lathe

With BN-K1 Solid CBN Insert, only need to steps can finish the whole process. It reduce the processing time, and improve the production efficiency. However it needs special tool holder. Halnn also can offer you, the image as follows:

If you have any problems on machining wear resistant parts, please feel free to contact with us info@halnntools.com, skype:info@halnntools.com, Whatsapp:+8615617635382