The application of heavy turning rolls with CBN Inserts

Category:News

PublishedDate:2017-08-18

Heavy turning is machining the surface of the rolls with large cutting depth. So it will require high on the high temperature red hardness, durability, impact resistance and stable performance because of its high hardness, large margine, long time working and high value.

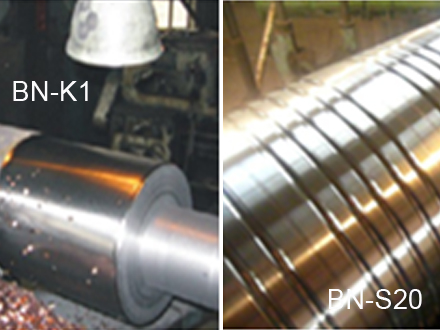

In current times, there are 3 types cutting tools materials: carbide insert, ceramic cutters and cbn insert. CBN Insert is the hardest cutting tools materials for machining ferrous metal materials, and is the first choice for heavy turning rolls. BN-K1 and BN-20 solid cbn insert is widely used in current times.

BN-K1 and BN-S20 belong to solid cbn insert, they use non-metal ceramic as binder, and they will improve the impact resistance while make sure high hardness and excellent wear resistance, and will not be chipping when meet irregular surface and casting defects. And BN-K1 solid cbn inserts are mainly used high hardness cast iron roll field, and BN-S20 solid cbn inserts are mainly used in high hardness alloy steel rolls industry. The cutting data as follows:

|

CBN Insert |

Machining Materials |

Recommend Cutting Data |

|

Cutting Speed Vc(m/min) |

Cutting Depth ap(mm) |

Feed Rate Fr(mm) |

|

BN-K1 |

Cast Iron Rolls |

350~120(Roughing) |

1~10 |

0.15~0.7 |

|

60~180(Finishing) |

≤1 |

0.05~0.35 |

|

BN-S20 |

Cast Steel Rolls |

50~150(Roughing) |

1~10 |

0.15~0.7 |

|

60~250(Finishing) |

≤1 |

0.05~0.35 |

(1)The application case of BN-K1 heavy turning cast iron rolls:

Rolls Materials: Ni-Cr Alloy Cast Iron

Rolls Hardness: HSD80

Insert Model: BN-K1 RNMN200800

Cutting Data: ap=4mm, Fr=1mm/r, Vc=55m/min

Machining Type: Dry Cutting

Compared with Ceramic Cutters, the advantages of BN-K1 solid cbn inserts as follows: The tool life of the single blade will be 6 times of ceramic cutter, at the base of 2 times feed rate.

(2)Application Case for heavy turning forged steel rolls with BN-S20 Solid CBN Insert:

Workpiece Materials: HSS Steel

Workpiece Hardness: HSD90

Insert Models: BN-S20 RCMX120700

Cutting Data: Vc=50m/min,Fr=0.2mm/r

Machining Type: Dry Cutting

Compared with carbide insert, BN-S20 solid cbn inserts advantages as follows: the machining flat will be about 15 percent of carbide insert. And the tool life of each blade will be 8.3 times of carbide insert, and the tool life is improved 6 times.

Any more information on machining rolls, please feel free to contact with us info@halnntools.com, Whatsapp:+8615617635382