The right tools BN-S30 Solid CBN for machining brake disc

Category:News

PublishedDate:2017-08-14

With the continuous development of the automotive industry, for the automotive brake system, a typical component - the demand for brake discs also increased. In this context, the brake disc processing technology has also changed. This article first introduced the two commonly used braking methods: disk brake and drum brake, and make a comparison. And make market analysis for the brake disc, that the brake disc manufacturing enterprises should improve the processing methods, improve production efficiency, then can survive in the current competitive environment.

1. The brief introduction of brake disc

There are two ways to brake: disc brake and drum brake. Now many cars are used the disc brake, because compared with both of us, the brake disc have the following advantages: disc brake has a good heat dissipation performance, will not produce heat failure because of high-speed b

; In addition, the disc brake will not appear brake failure phenomenon be due to continuous brakes to ensure that driving safety. And it has simple structure, is easily repaired.

2. The processing requirements of brake disc

Brake disc is an important part of the brake system, good brake disc brake has stable performance, no noise, no Jitter. So it required high on the process, as following:

(1) Brake disc belong to casting products, the surface requirements can’t exist trachoma, porosity and other casting defects, to ensure that Brake disc strength and stiffness, to prevent the occurrence of the accident.

(2) When Disc brakes, it uses two brake surface, so it required high on the brake surface quality, and also need to ensure the position accuracy.

(3) It will produce high temperature when brake, the middle of the brake disc should be designed duct, and is easily to heat.

(4) The middle hole of the brake disc is the main benchmark for the assembly. So the process of processing holes is particularly important. In current, we use Halnn BN-S30 solid cbn insert for this process.

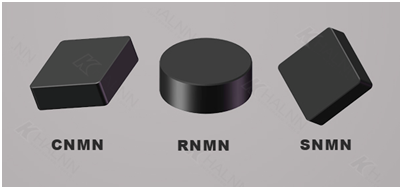

3. The cutting tools selection of processing brake disc

BN-S30 are already widely used in the brake disc industry. BN-S30 Solid CBN can make sure the good surface roughness, and improve the working efficiency, and realize stable performance.

The application Case as follows:

(1) Machining Process: Roughing and Finishing

(2) Cutting Data: ap=2.5mm, Fr=0.45mm/r, Vc=350m/min

(3) Machining Type: Dry Cutting

Compared with carbide insert and BN-S30 solid cbn, BN-S30 Solid CBN Insert has the following advantages: It can realize high cutting speed, and has high efficiency and good roughness. As we can know that BN-S30 Solid CBN is the right choice for machining brake disc.

If you would like to know more information on Halnn solid cbn, please click http://www.halnncbn.com/Products/solid_cbn_inserts/ , Or feel free to contact with us info@halnntools.com, Whatsapp:+8615617635382