The application of Halnn CBN Inserts on air-conditioning com

Category:News

PublishedDate:2017-08-11

As the air conditioning compressor bearing is one of the main part that adjust the temperature, with the market competition continues to intensify, how to ensure product quality, and improve production and reduce production costs at the same time have become the most important problem.

CNC Machine Tools are widely used in air conditioning compressor industry. And it required high on the cutting tools precision, efficiency and tool life. Traditional cutting tools have low price, but it has low efficiency, which lead to the high production costs.

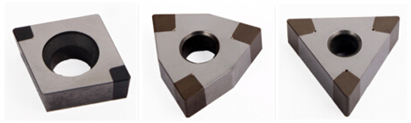

Now we use Halnn BN-K20 Brazed PCBN insert machining air-conditioning compressor upper bearings which can realize high speed cutting, the highest speed can reach 1500m/min. And the tool life of high cutting speed can be several times of traditional cutting tools. All costs will be reduced.

Application Case of cbn inserts machining air-conditioning compressor upper-bearings:

Machining Materials: FC250

Workpiece Hardness:HB220~260

Insert Model: BN-K20

Cutting Data: Vc=800m/min, Fr=0.25mm/r,ap=0.3mm

Testing Performance: Comparing with coating carbide insert, the cutting speed can be 2~3 times of coating carbide insert, and the tool life will be 6 times of coating carbide insert.

|

Insert Materials |

Cutting Speed(m/min) |

Insert Life(pieces) |

|

Halnn BN-K20 |

800 |

500 |

|

Coating Carbide Insert |

330 |

80 |

With BN-K20 PCBN Insert machining the upper bearing of the air-conditioning compressor, it not only reduces the change insert frequency, lower the productivity, and improve the efficiency, reduce the costs. And we need to use dry cutting, no need cutting fluid.