Different cbn insert Grades for machining gray cast iron

Category:News

PublishedDate:2017-07-28

CBN Insert, we all know that the main application areas are high hardness cast iron/hard steel and other fields, and Gray cast iron is the most common in this field. Especially for roughing and CNC machining, cbn inserts are more widely used.

The hardness of Gray Cast iron is low, so the traditional tools can process, but why do many manufacturers choose cbn inserts whose price is more expensive? The reasons are as follows:

1) Gray cast iron material are mainly used in machine tools, automotives and other industries, most parts are mass production, and it requires higher production efficiency, although the traditional tool can also be used for processing gray cast iron, but the processing efficiency is low, only suit for small batch production and occasionally processing gray cast iron parts.

(2) Now the mass production of gray cast iron parts of the enterprises mainly use CNC lathe processing, many people are aware of traditional cutting tools can’t be used with high-speed cutting, when the linear speed over the maximum line speed (350m/min) ,it will appear severe wear and tear, thus it will affect production efficiency and Surface quality of work pieces.

(3) CBN Inserts, because of its high hardness, excellent wear resistance, the linear speed on fine finish turning gray cast iron can be up to 1000m/min, which is suitable for mass production of gray cast iron parts with CNC lathes. And it also can guarantee a high degree of smoothness and flatness and other requirements.

Halnn, more than 10 years of focusing on processing hard materials, has become the famous brand in cutting tools industry. And with the long-term training accumulated technical strength and the most cutting-edge technology development capability, Halnn first propose the concept of rough processing with "cubic boron nitride polycrystalline blade overall" in China, and adapt to the contemporary "high-speed, precision machining" and other cutting requirements. Halnn has good materials in the gray cast iron field.

According to the gray cast iron processing procedures and precision requirements, Halnn developed 3 cbn inserts grades, the following will show you the advantages:

According to the classification of processing procedures:

(1) Roughing process, select the solid cbn inserts BN-S30, the advantage is: Large cutting depth, excellent wear-resistance, long lifetime;

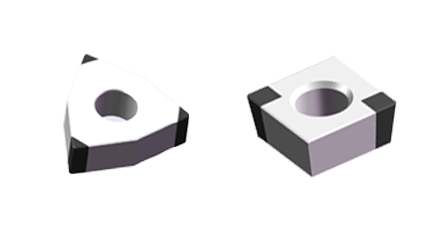

(2)Semi-finishing: Select solid cbn inserts BN-S300, the advantage are: high sharpness of the blade, high precision, long tool life

(3) Finishing: Select the brazed PCBN Inserts BN-K20, the advantage is: high cutting speed, edges more economical, and the blade is more flexible way to step up.

Halnn also developed a tool which can be simultaneously processed gray cast iron parts, for example the brake disc, the original processing process for the processing one side of the part, after that exchange the other side of processing, Halnn use a Clamping tool which can machining the upper and lower face at the same time, it not only reduces the production time of 50%, and flatness to maintain a better and more efficient.

Such as following application case

Halnn solid cbn inserts BN-S300 finish turning gray cast iron brake disc

|

Halnn solid cbn inserts BN-S300 finish turning gray cast iron brake disc

|

|

Machining Work piece: Brake Drum

|

|

|

Machining Process: Finishing

|

|

Machining Part: End Surface

|

|

Insert Grade:BN-S300 SCGN090408

|

|

Machining Type: Machining with 2 inserts at the same time

|

|

Cutting Parameters: ap=0.25mm,Fr=0.2mm/r,Vc=800m/min

|

|

Machining Type: Dry Cutting

|

|

Testing Result

|

|

Insert Materials

|

Insert Grade

|

Linear Speed

|

Lifetime per blade

|

|

Halnn BN-S300

|

SCGN090408

|

800m/min

|

300 pieces

|

|

Coated Carbide insert

|

CNMG120408

|

300m/min

|

15 pieces

|

If you have any problems on solid cbn inserts,Please check http://www.halnncbn.com/Products/solid_cbn_inserts/, or contact with us directly info@halnntools.com ,whatsapp:+8615617635382