As we all know, mill rolls can be divided into 2 main kinds, which are cast iron rolls and cast steel rolls. Because it will have defects in the casting process, so it always be a problem on machining mill rolls.

Halnn, as the predecessor of superhard cutting tools, always devote to researching new materials to satisfy the manufacturers’ requirements, and has high repution on superhard cutting tools field.

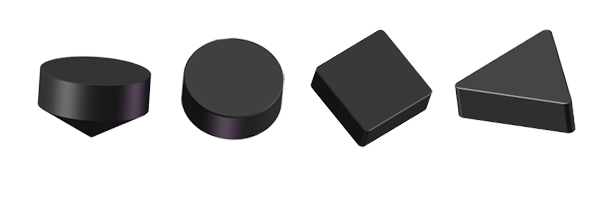

Specific for mill rolls, Halnn researched BN-S20 and BN-K1 cbn inserts. Both of the 2 grades belong to solid cbn inserts. Solid CBN Insert is new material which hardness is only second to diamond, is one of the cutting tools which can be used for high cutting speed, high precision and high efficiency. Both of BN-S20 and BN-K1 solid cbn inserts have excellent wear resistance, strong Fracture resistance which will help the manufacturer realize good performance and high efficiency and help them lower the tool cost and expand the tool life. The differences of them are as belows: BN-K1 solid cbn inserts are mainly for cast iron rolls, while BN-S20 solid cbn inserts are mainly for cast steel rolls.

The following will share you one of the application case for reference.

|

Halnn Solid CBN Inserts BN-K1 heavy turning cast iron rolls

|

|

Workpiece

|

Cast Iron Rolls

|

|

|

Hardness

|

HSD80

|

|

Cutting Fluid

|

Dry Cutting

|

|

Cutting Data

|

ap=4mm,Fr=1mm/r,Vc=55m/min

|

|

Testing Performance

|

|

Insert Materials

|

Feed Rate(mm/r)

|

Tool Life(pcs/blade)

|

|

Halnn BN-K1

|

1

|

3

|

|

Ceramic Cutter

|

0.5

|

0.5

|

Compared with Ceramic Cutters, the feed rate of Halnn BN-K1 is 2 times of ceramic cutter, while the tool life is 6 times of ceramic cutters. It improves the efficiency obviously and lower the tool costs.

With BN-K1 and BN-S20 solid cbn insert heavy turning rolls, it not only has more cutting edges, but also has excellent performance, the common cutting tools will not be balance with them. And BN-K1 solid cbn inserts can be used for both roughing and finishing process, also will be make sure the dimension precision and the roughness requirements.

If you have any problems on machining rolls, please feel free to contact with us info@halnntools.com, Whatsapp:+861869586134