|

BN-K10 processing Hip joint supporter

|

|||

|

Machining Part:Hip joint supporter

|

Machining Materials:Cobalt-chromium alloy

|

||

|

Workpiece Hardness:HRC 35

|

Inserts Grade:BN-K10 DCGW11T304

|

||

|

Cutting Type:Dry Cutting

|

Cutting Parameters:ap=0.15mm,Fr=0.10mm/r,Vc=210m/min

|

||

|

Testing Performance

|

|||

|

Inserts Materials

|

Linear Speed(m/min)

|

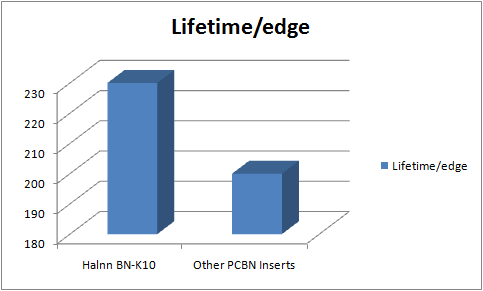

Lifetime/edge

|

Flank wear/mm

|

|

Halnn BN-K10

|

210

|

230

|

0.4

|

|

Other PCBN Inserts

|

180

|

200

|

0.5

|

From above tablet, we can see that the tool life of Halnn Bn-K10 will improve 15%, and the cutting speed also improve, thus improve the working efficiency.