There are many types of hardened steel. Only when we choose the right tool brand can we solve the problem better and more effectively and improve the processing efficiency.Halnn developed different tool brands for different hardened steel parts, the specific brands are shown in the following table.

(1) Continuous Cutting Conditions:The BN-H05 and BN-H11 materials are recommended.They can achieve high-speed cutting.Compared with ceramic blades, our tool life is increased N times, and we can also provide coated CBN inserts.

(2) Medium Intermittent Cutting Conditions:The BN-H10 and BN-H20 materials are recommended.In hard turning, the tools of these two materials can withstand the impact of the keyway.At the same time, it is decided whether the grinding machine can be used in the hard turning process stably.

(3) Strong Intermittent Cutting Conditions:Composite CBN inserts BN - H21 material are recommended.BN-H11 has high cost performance and stable cutting performance when hard machining gears with group holes on the end face.

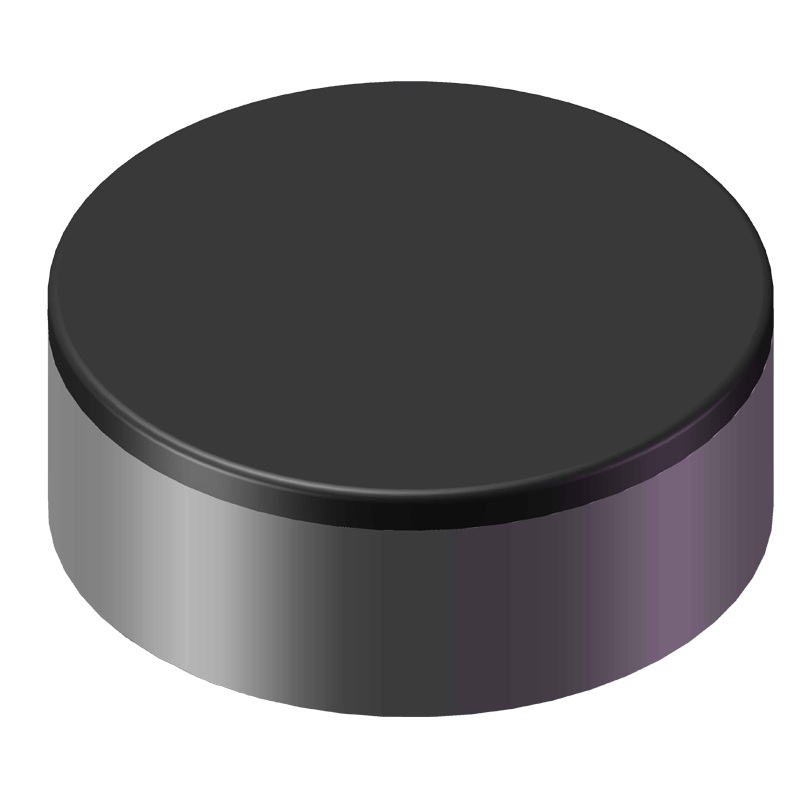

(4) Heavy-Duty Cutting Conditions:Overall polycrystalline CBN blade BN-S20 is recommended.When hard turning, it can withstand the impact of tooth surface, its cutting performance is stable, cost-effective.

| Cutting Tool Brand | Suitable Processing Mode | The Depth of Turning | The State of Being Machined | Recommended Machining Hardness |

| BN-S20 | Rough Machining, Semi-Finishing | 0.5mm--10mm | Intermittent - Continuous | HRC45-HRC68 |

| BN-S200 | Finishing | ≤1mm | Continuous Finishing | HRC45-HRC68 |

| BN-H21 | Finishing | ≤0.5mm | Medium Intermittent - Strong Intermittent | HRC58-HRC68 |

| BN-H20 | Finishing | ≤1mm | Medium Intermittent | HRC45-HRC63 |

| BN-H11 | Finishing | ≤1mm | Continuous Cutting | HRC45-HRC63 |

| BN-H10 | Finishing | ≤0.5mm | Continuous - Intermittent | HRC45-HRC68 |

| BN-H05 | Finishing | ≤0.2mm | Continuous Cutting | HRC45-HRC68 |

| BN-H05 C25 | Finishing | ≤0.2mm | Continuous Cutting | HRC45-HRC68 |

| BN-H10 C25 | Finishing | ≤0.5mm | Continuous - Intermittent | HRC45-HRC68 |

| BN-H21 C25 | Finishing | ≤0.5mm | Medium Intermittent - Strong Intermittent | HRC58-HRC68 |

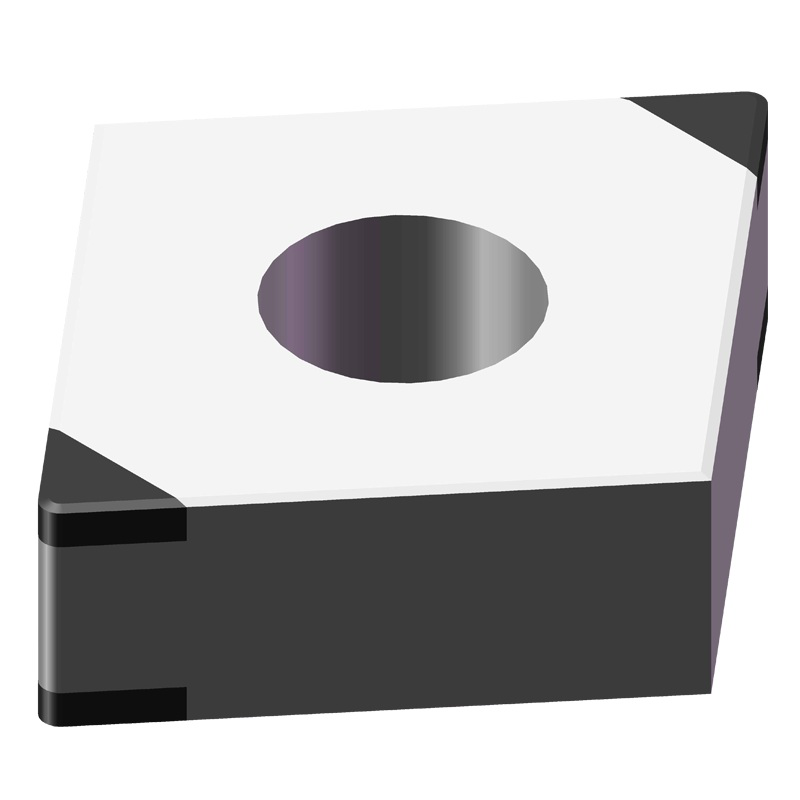

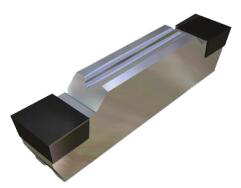

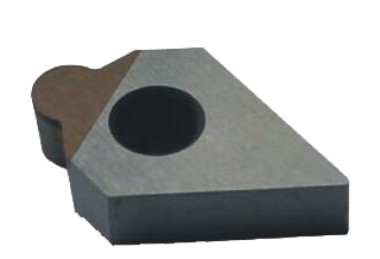

| Tool Drawing For Quenching Steel | |||

|

|

|

|

|

|

|

|

| Gears |

(1) Continuous Cutting Conditions:The BN-H05 and BN-H11 materials are recommended.They can achieve high-speed cutting.Compared with ceramic blades, our tool life is increased N times, and we can also provide coated CBN inserts.

|

The workpiece material:20CrMnTi(Hardness HRC58-62) Insert Type:BN-H05 CNGA120408 Cutting Parameters:Vc=180m/min,Fr=0.1mm/r,ap=0.1mm Cutting Method:Dry Cutting |

|

| Cutting Tool Material | Surface Roughness | Tool Life |

| Halnn BN-H05 material | ≤Ra0.8 | 800 pieces |

| Other Brand CBN | Ra1.0 | 550 pieces |

(2) Medium Intermittent Cutting Conditions:The BN-H10 and BN-H20 materials are recommended.In hard turning, the tools of these two materials can withstand the impact of the keyway.At the same time, it is decided whether the grinding machine can be used in the hard turning process stably.

|

The Workpiece Material:20CrMnTi(Hardness HRC58-62) Insert Type:BN-H10 CCGW09T304 Cutting Parameters:Vc=135m/min,Fr=0.08mm/r,ap=0.25mm Cutting Method:Dry Cutting |

||

| Cutting Tool Material | Cutting Speed | Tool Life | Efficiency |

| Halnn BN-H10材质 | 135m/min | 1000 pieces | Improved 22% |

| Other Brand | 110m/min | 600 pieces | ---- |

|

The Workpiece Material:20CrMnTi(Hardness HRC58-62) Insert Type:BN-H21 WNGA080404 Cutting Parameters:Vc=117m/min,Fr=0.1mm/r,ap=0.15mm Cutting Method:Dry Cutting |

|

| Cutting Tool Material | Tool Life | Final failure mode |

| Halnn BN-H21 | 600 pieces | Normal wear and tear |

| Other Brand | 100 pieces | Destroied |

(4) Heavy-Duty Cutting Conditions:Overall polycrystalline CBN blade BN-S20 is recommended.When hard turning, it can withstand the impact of tooth surface, its cutting performance is stable, cost-effective.

|

The Hardness of Workpiece:HRC60 Insert Type:BN-S20 SNMN120712 Cutting Parameters:Vc=90m/min,Fr=0.12mm/r,ap=2.5mm Cutting Method:Dry Cutting |

||

| Cutting Tool Material | Cutting Speed | Tool Life | Final failure mode |

| Halnn BN-S20 | 90m/min | 0.5 piece/blade | Normal Wear and Tear |

| Other Ceramic Cutting Tool | 45m/min | 0.3 piece/blade | Destoried |