| Insert Grade | Suited Materials | Machining Type | Typical Application | Insert Image |

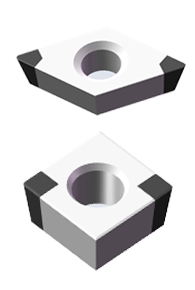

| BN-K1 | Chilled Cast Iron, Hi-Ni-Cr Cast Iron and High harness alloy cast iron | Roughing | Alloy Cast Iron, Slurry Pump, Wear resistant castings |  |

| BN-S10 | High Speed Steel | Roughing | HSS Rolls |

| BN-S20 | Hardened Steel, Heat and abrasive resistant steel, High manganese steel | Roughing, Semi-Finishing | HSS Rolls, Ball Screw, Wind Power Bearings |

| BN-S200 | Hardened Steel, Superalloy | Finishing | Wind Power Bearings |

| BN-S300 | Gray Cast Iron | Roughing, Finishing | Brake Disc, Cast Iron Engine,Gearbox, Cylinder Liner |

| BDN80 | Ni-based alloy, Stellite Alloy, Superalloy | Roughing, Finishing | Aircraft turbine disk, Ni based alloy parts |

| BN-H11 | Hardened Steel | Semi-Finishing, Finishing | Bearings, Gears, Gear Shaft, Hardened Mold |  |

| BN-H20 | Hardened steel, other materials of difficult to machine | Semi-Finishing, Finishing | Hardened Steel Gears, Mold,ect |

| BN-K20 | Gray Cast Iron | Semi-Finishing, Finishing | Brake Disc, Cast Iron Engine,Gearbox |

| BNK30 | Gray cast iron, Iron based alloy | Semi-Finishing,Finishing | Brake Disc, Brake Drum, Cast Iron Engine, Gearbox |

| BN-K50 | Powder Metallurgy | Finishing | Powder Metalurgy Valve seat |

| BN-H05 | Hardened Steel | Finishing | Gears,Gear Shaft, Bearings |  |

| BN-H10 | Hardened Steel, high strength cast iron | Finishing | Bearings, Gears, Gear Shaft, High hardness component |

| BN-H21 | Hardened Steel | Finishing | Bearings, Gears, Gear Shaft,Mold,ect. |

| BN-K10 | Gray Cast Iron, Powder Metallurgical | Finishing | Valve seat ring; Engine cylinder bore; Powder Metallurgy parts |

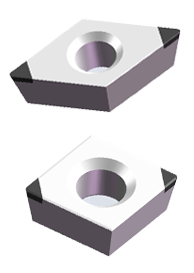

| BN-H05 C25 | Hardened Steel | Finishing | Bearings, Gears, Gear Shaft, Mold,ect |  |

| BN-H10 C25 | Hardened Steel | Finishing | Bearings, Gears, Gear Shaft, High hardness components |

| BN-H21 C25 | Hardened Steel | Finishing | Bearings, Gears, Gear Shaft, Mold,ect |