1. PCD Grade and Application

| Grade | Granularity(μm) | Characteristics | Application | Microstructure |

| CDW850 | Submicron | Ultra-fine grain structure, strong edge sharpness and edge durability | High precision machining, mirror surface machining, suite for aluminum alloy that required high on the chipping performance, mainly used for machining Ti alloy and other composites | .png) |

| CDW002 | 2μm | High cobalt content, Good electrical machine performance, excellent toughness, Good roughness machining, more convinent for complec tool processing | Mainly used for engrave milling cutter and thread cutting tool, and also cutting tools for wear-resistant parts, used in woodworking saws, particleboard and the tools for machining silicon aluminum alloy | .png) |

| CDW005 | 5μm | Excellent electric spark and machinability, good toughness, wear resistance and edge quality | It suits for good surface quality processing, mainly used for machining PMMA, Silicion alloy and metal cell phone shell outlin and used in the wood cutting tools, saws industry | .png) |

| CDW010 | 10μm | Universal PCD Grade, good toughness and high abrasive resisitance | Suit for single tool for rough machining, especially for wood molding, medium and low silicon aluminum alloy parts (such as piston) | .png) |

| CDW025 | 25μm | High wear resistance and edge quality | Suit for high Silicion Aluminum alloy, MMC, Tungsten carbide and ceramic, graphite,wear resistant parts, mainly used in wood Wood finishing insert and saws | .png) |

| CDW302 | 2~30μm | Mixed 2μm and 25μm,good wear resistance and edge quality and edges strength | It mainly used for machining MMC, high Silicion Aluminum calloy, high strength cast iron and other application. | .png) |

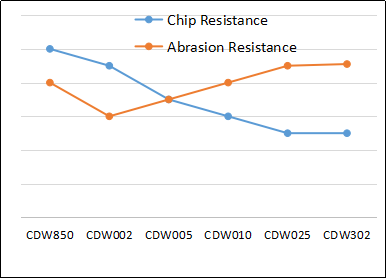

2. PCD Grade and Machining Characteristics

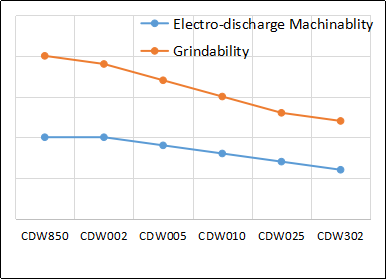

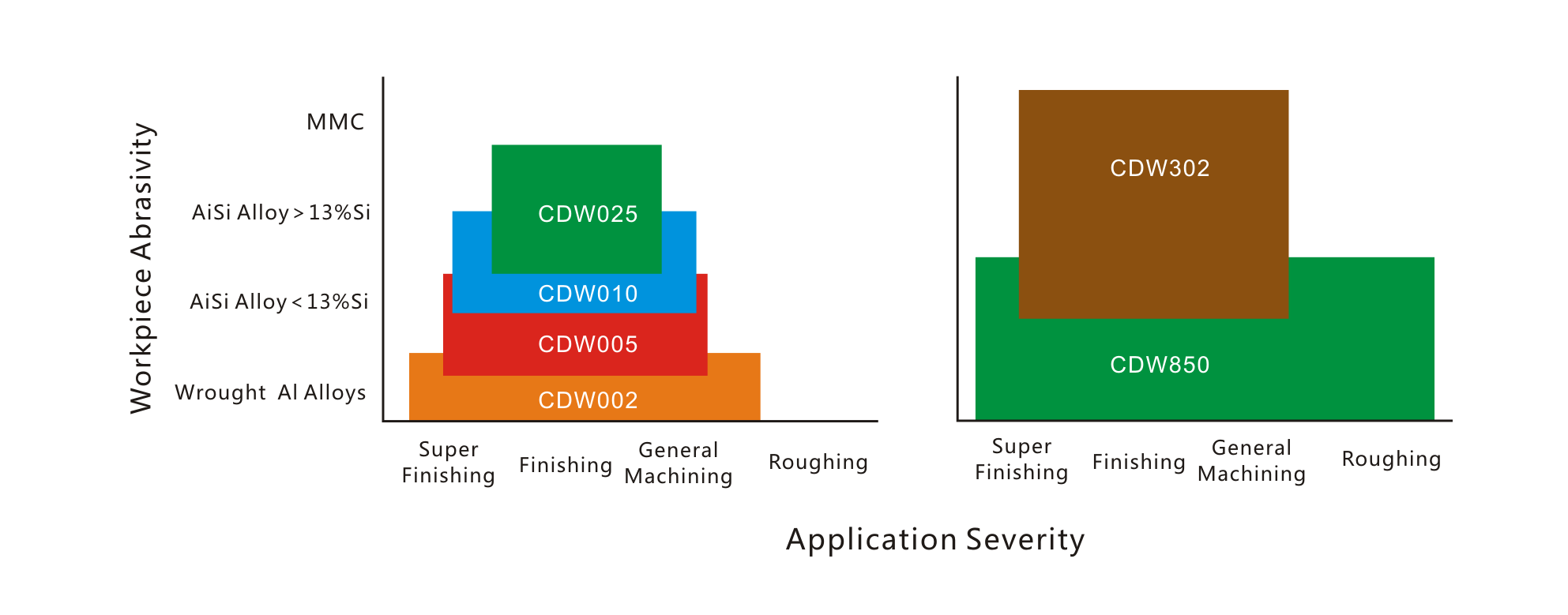

3.Choosing the suitable PCD Grade for your Application

4. Halnn recommend cutting condition

| Component Materials | Recommend PCD Grade | Vc(m/min) | Fr(mm/r) | ap(mm) |

| Aluminum Alloy (4~8% Si) | CDW010 | CDW302 | CDW005 | CDW850 | 100-5000 | 0.03-0.5 | 0.1~3.0 |

| Aluminum Alloy (9~13% Si) | CDW010 | CDW302 |

| CDW850 | 100-3000 | 0.03-0.5 | 0.1~3.0 |

| Aluminum Alloy (>13% Si) | CDW010 | CDW302 | CDW025 | CDW850 | 100-2500 | 0.03~0.4 | 0.1~2.5 |

| Copper alloy( Copper,Brass) | CDW010 | CDW302 | CDW025 | CDW850 | 100-1000 | 0.03~0.3 | 0.1~3.0 |

| Titanium Alloy | CDW850 | CDW005 |

|

| 100-200 | 0.05~0.2 | 0.1~2.0 |

| Tungsten Carbide(Co>16%) | CDW302 | CDW025 | CDW010 |

| 15-40 | 0.1~0.25 | 0.1~1.0 |

| Tungsten Carbide(Co<16%) | CDW302 | CDW025 | CDW010 |

| 10-30 | 0.03~0.1 | 0.05~0.3 |

| Wood | CDW010 | CDW302 | CDW005 | CDW002 | 100-4000 | 0.1~0.4 | 0.1~3.0 |

| Graphite | CDW302 | CDW025 | CDW010 |

| 100-600 | 0.1~0.5 | 0.05~2.0 |

| Metal Matrix Composites | CDW302 | CDW025 | CDW010 |

| 300-600 | 0.1~0.4 | 0.2~1.5 |

| Composites(Carbon Fiber) | CDW302 | CDW025 | CDW010 |

| 200-2000 | 0.05~0.3 | 0.1~3.0 |